Add to Cart

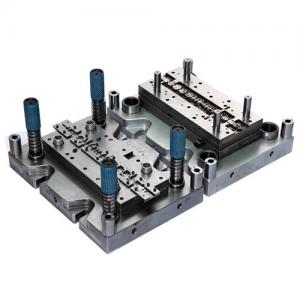

OEM ODM Customized Precision Sheet Metal Progressive Stamping Die

Definition

According to the structure, stamping die can be divided into three categories: single stage die, composite die and progressive die.

The first two types require more human assistance and are suitable for small-scale production of some products or products with specific processes.

A high-speed progressive stamping die is suitable for mass-producing hardware products to reduce costs, improve efficiency and ensure quality. It is characterized by high development and production cost, high production efficiency, and stable product quality (pay attention to the spacing between modules, machining accuracy of parts, assembly accuracy, matching accuracy and interference problems, so as to achieve the purpose of automatic mass production of progressive die).

Structure

1. Stage Die

2. Compound Die

3. High-Speed Progressive Stamping Die

Mold Processing Technology and Equipment

It can be seen from the above die structure diagram that the structure of the high-speed continuous stamping die is relatively complex, which is necessary to ensure stable quality during the high-speed stamping process.

Our company has a professional mold design team supplemented by advanced design software PRO-E, CAD, CAM, etc. to carry out data analysis and simulation in the early stage, and then process and produce after obtaining reasonable data.

Mold motherboard processing technology: CNC milling machine processing - vacuum heat treatment - ultra-cryogenic treatment (stress relief) - precision grinding (flatness +-0.002) - slow wire cutting - JG inner hole grinding - quality inspection, only in the seven processes described Only after fully qualified can the molds be assembled.

Parts processing technology: CNC wire cutting (ordinary parts are immersed in water machine, important parts are immersed in oil), PG optical curve grinding, precision grinding, and other processes, the engineering accuracy of parts can be controlled within +-0.001mm.

Mold material: Hitachi DC53/SLD is used for the main board of the template, SKD11 is used for the backing plate, SKH-9 is used for forming the part material, and tungsten steel KD20 is imported for the blanking size parts. Guide parts: MITSUMI ball type guide post guide bush.

Mold processing equipment: including AgieCharmilles WEDM, Japanese original Sodick WEDM, oil cutting machine, Taiwan precision grinder, Japan AMADA Vasino optical curve grinder, the precision image measuring instrument, projector, hardness tester, etc.

Technical Characteristics of Our Company

We specialize in the production of high-speed continuous metal stamping dies suitable for high-precision products that require mass production, such as connector terminals, electronic accessories, etc., which can be continuously electroplated and assembled automatically. The mold production speed is 200-1000SPM/min, and the mold life can reach more than 100 million mold times.

We specialize in the production of difficult continuous stamping dies suitable for complex processing such as riveting, tapping, secondary stamping, stacking and other types of products that require automation equipment. The mold production speed is 200-1000SPM/min, and the mold life can reach more than 100 million mold times.

Packing & Shipping

Certification

Shenzhen Huishuo Precision Technology Co., Ltd - China Professional OEM ODM Manufacturer/Supplier/Maker of Custom Precision Sheet Metal Stamping Products, Progressive Metal Stamping Die, Plastic Injection Mold and Plastic Injection Parts.

About Us

Huishuo Ltd., established in August 2009, is an OEM/ODM Chinese manufacturer specializing in the design and manufacture of progressive metal stamping dies, deep draw dies, plastic injection dies, precision sheet metal stamping and plastic injection products. Stamping products include precision terminals, connectors, electronic shielding cases, metal housing, precision shrapnel, battery contact chips, metal brackets, electronic radiator/heat sinks, and so on, ranging from small to complex size, metal and plastic components. Our products are widely used in hundreds of applications, for example, precision connector terminals, relay shrapnel, micro motor shrapnel, IC lead frames, automotive terminals, home appliance precision shrapnel, intelligent electronic components, medical terminals and other consumer electronic parts industries.

Our Services and Products

- Tool & Die Design and Prototype

- Wire EDM

- Optical Profile Grinding (PG)

- CNC Machining

- Metal Stamping Die Manufacturing & Assembly

- Sheet Metal Stamping/Fabrication

- Plastic Injection Molds/Molding

- Automated Production Line

Scope of Application

- Information products

- Car, motorcycle

- Phone / mobile phone

- PC computer

- Medical products

Why High-Speed Progressive Stamping Die?